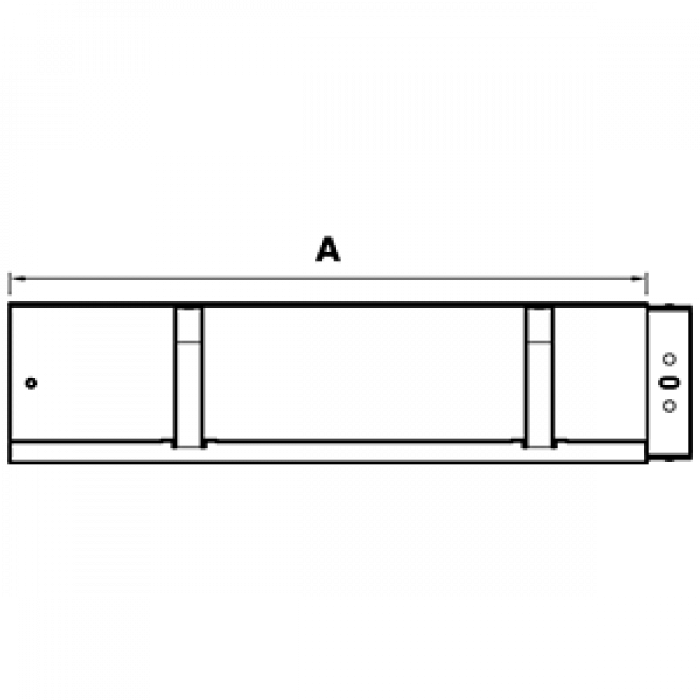

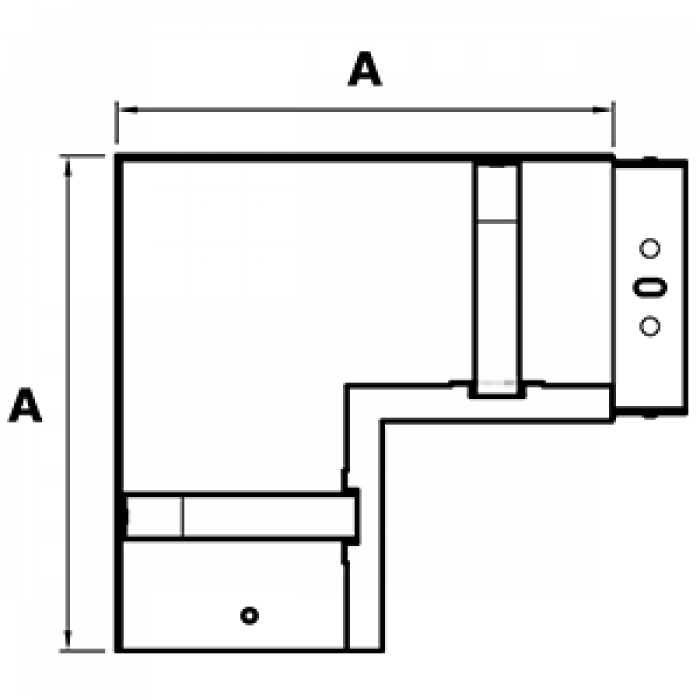

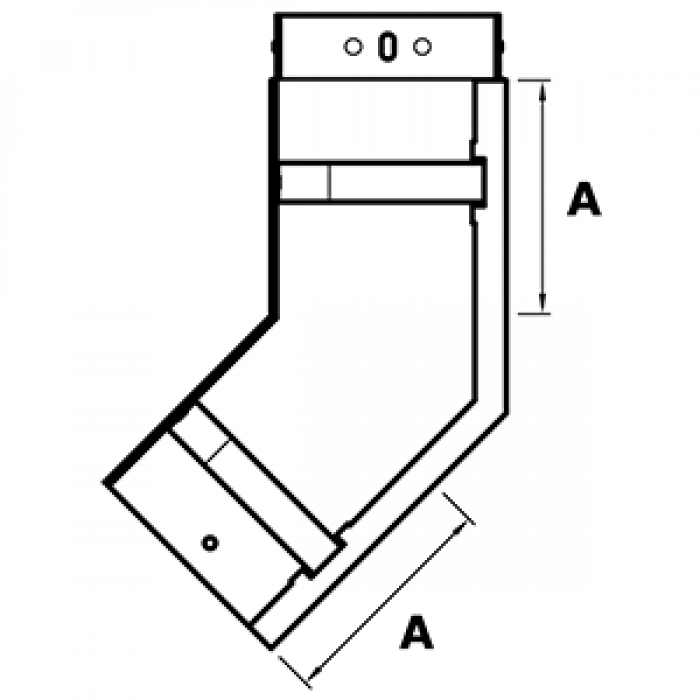

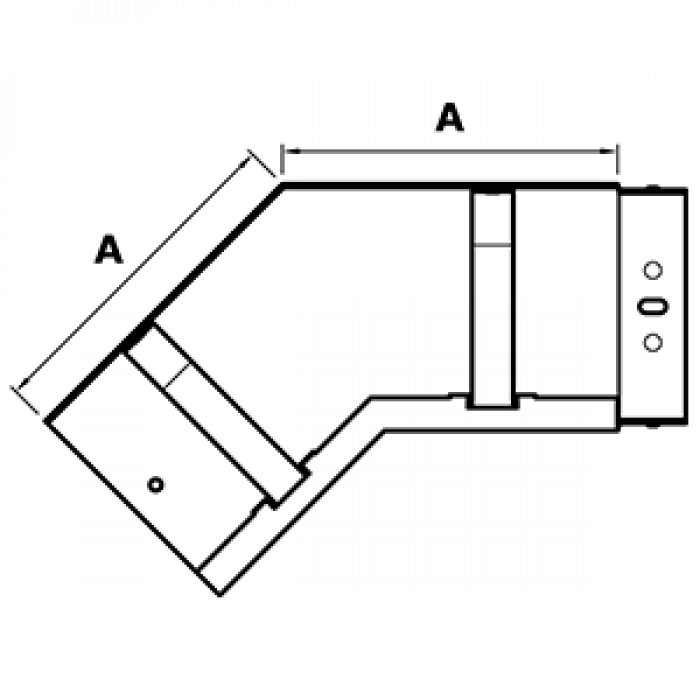

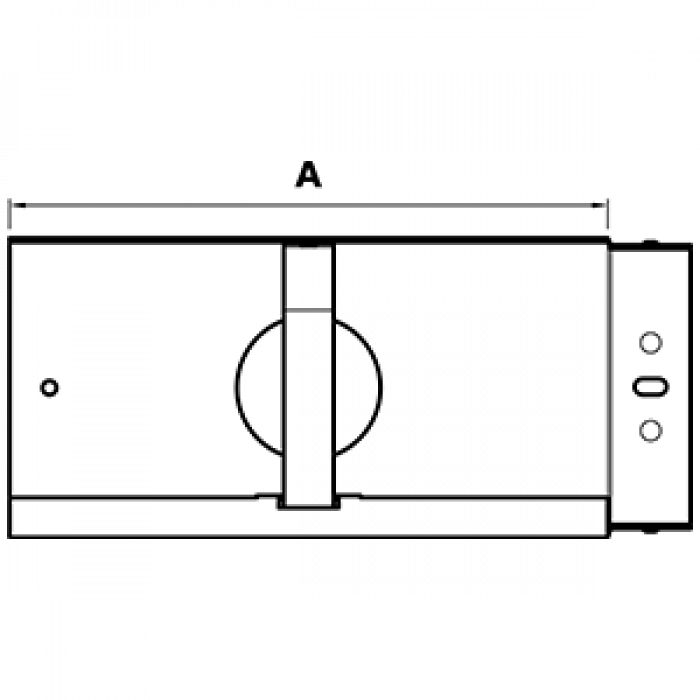

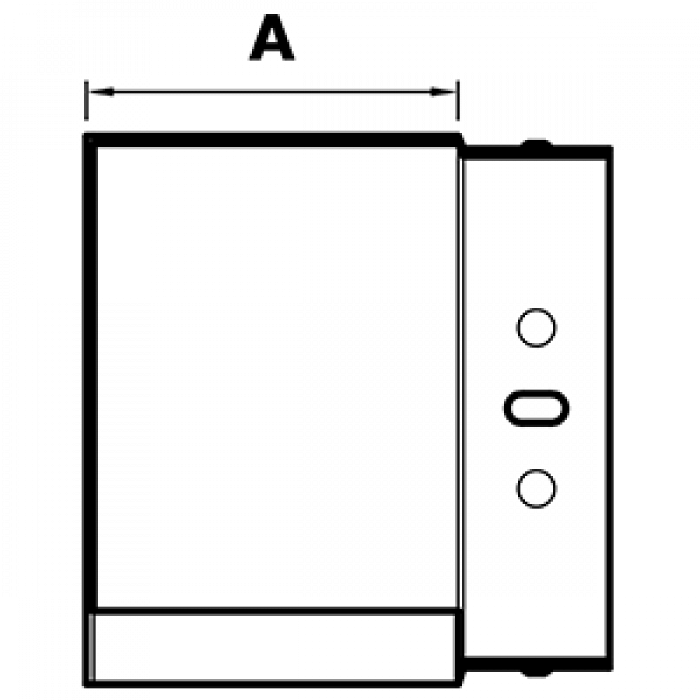

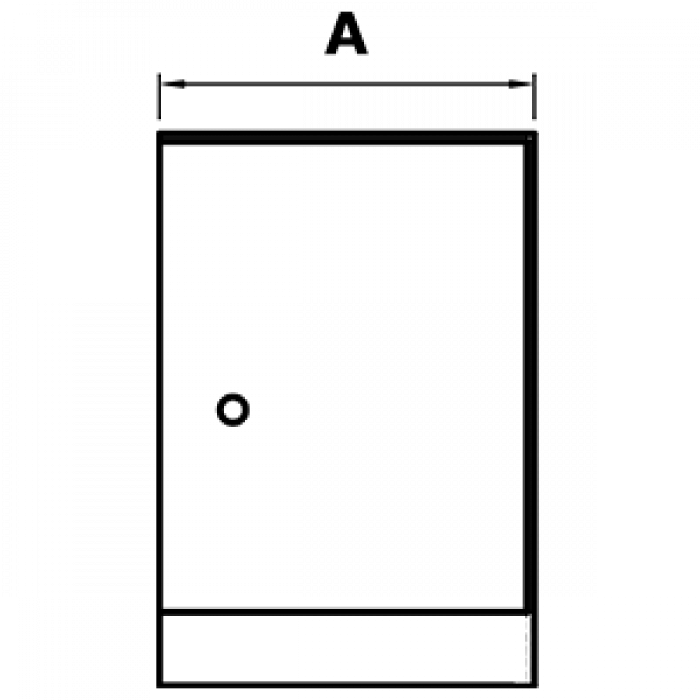

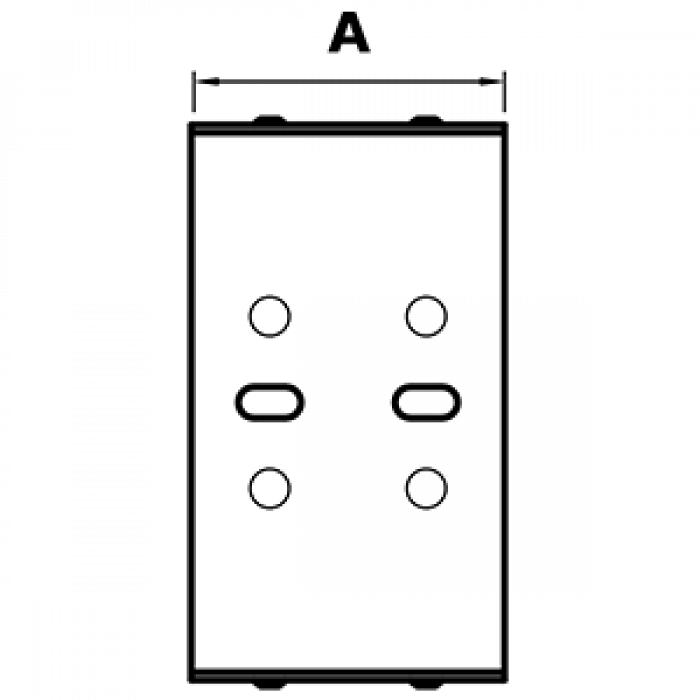

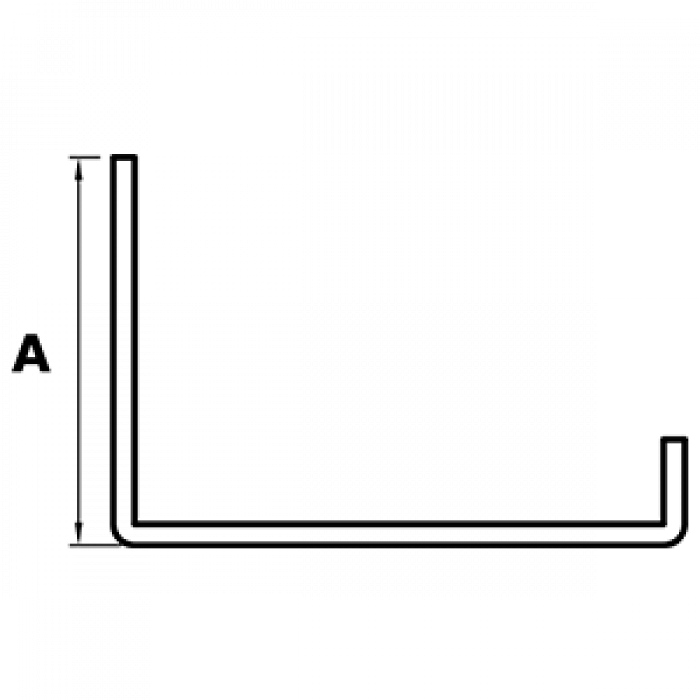

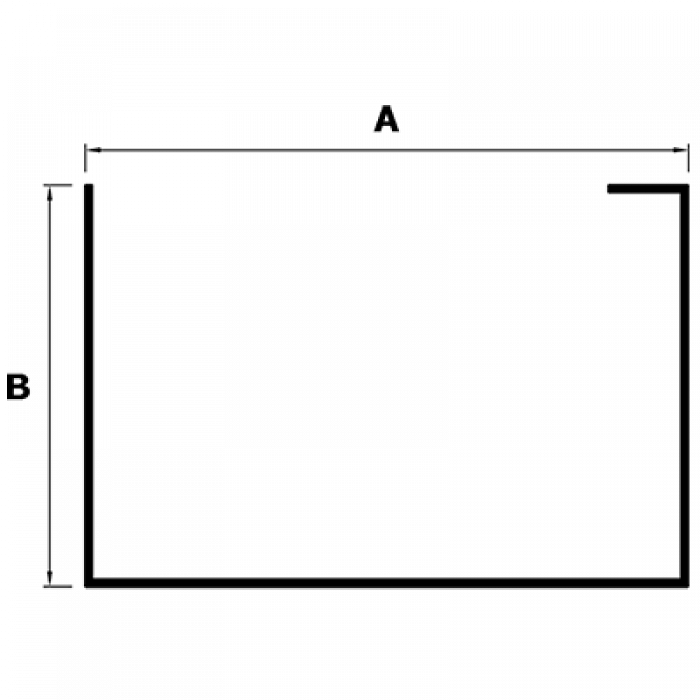

| A | B |

|---|---|

| 100 | 75 |

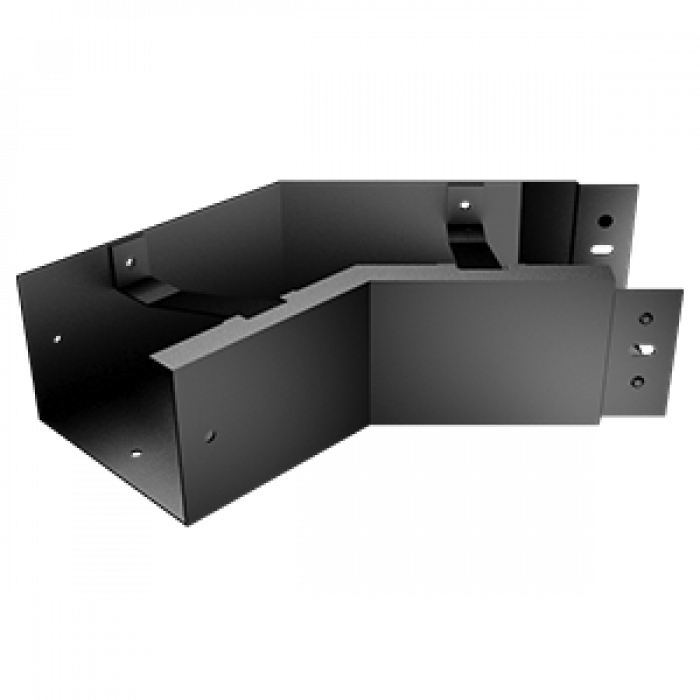

| 125 | 100 |

| 150 | 100 |

| 150 | 150 |

| 200 | 150 |

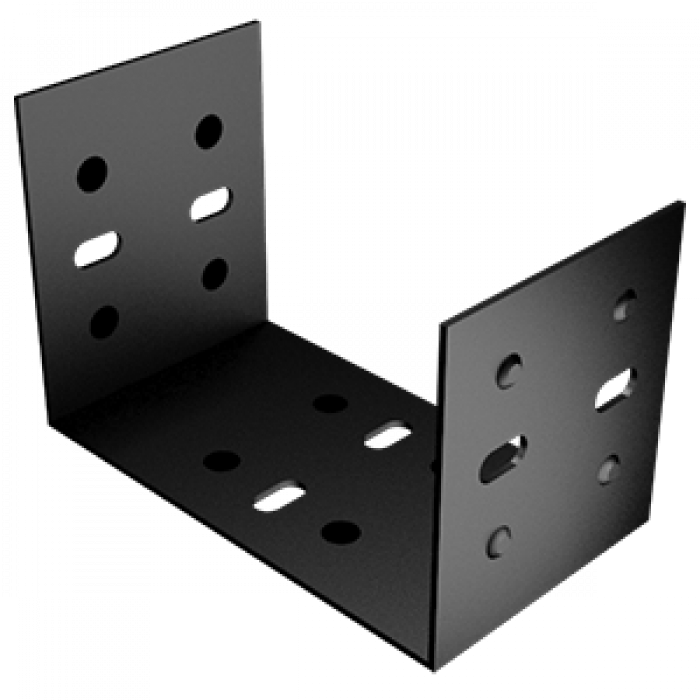

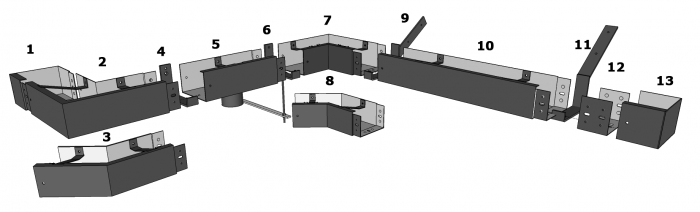

| Number | Item |

|---|---|

| 1 | Left Hand Stop End |

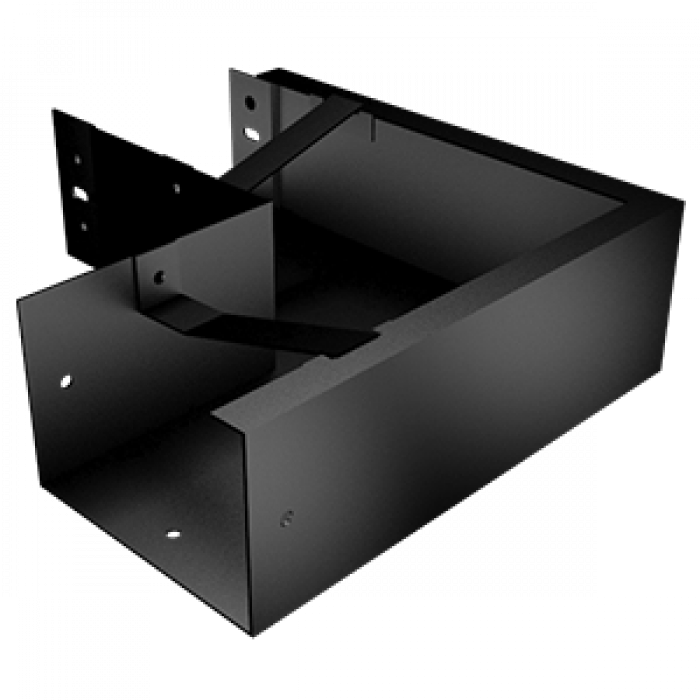

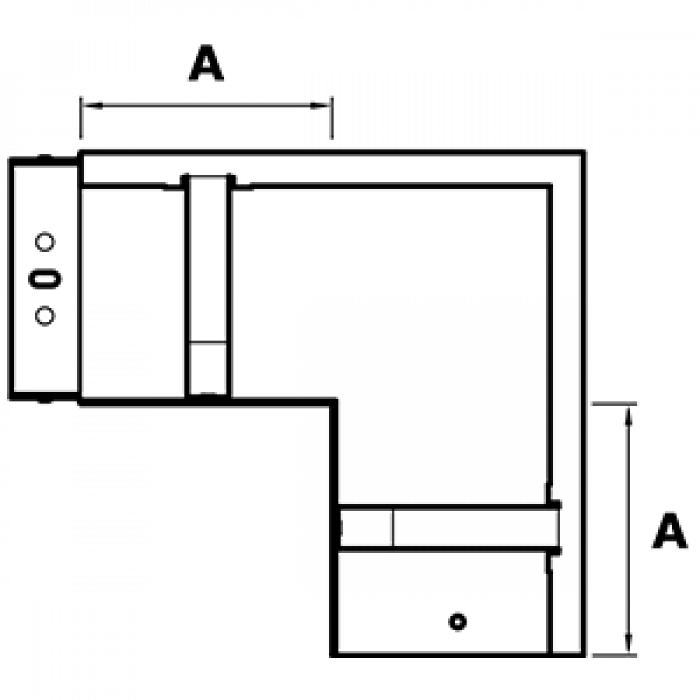

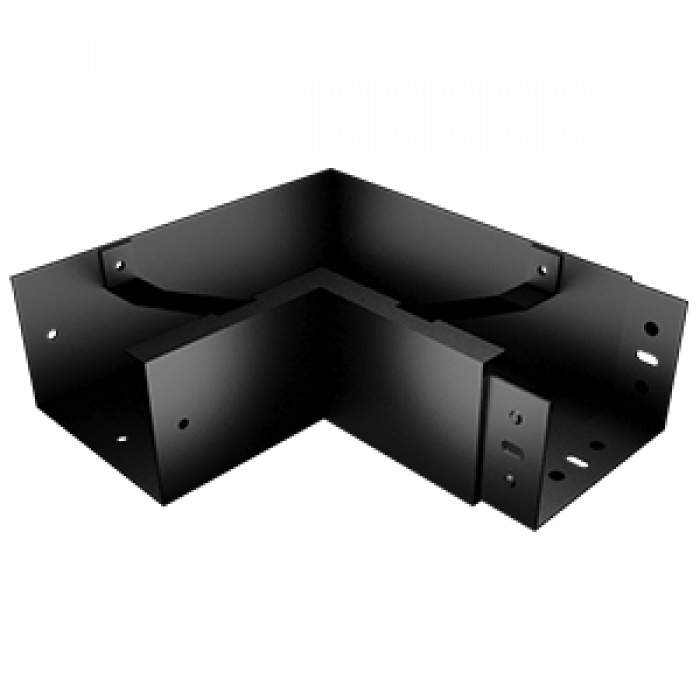

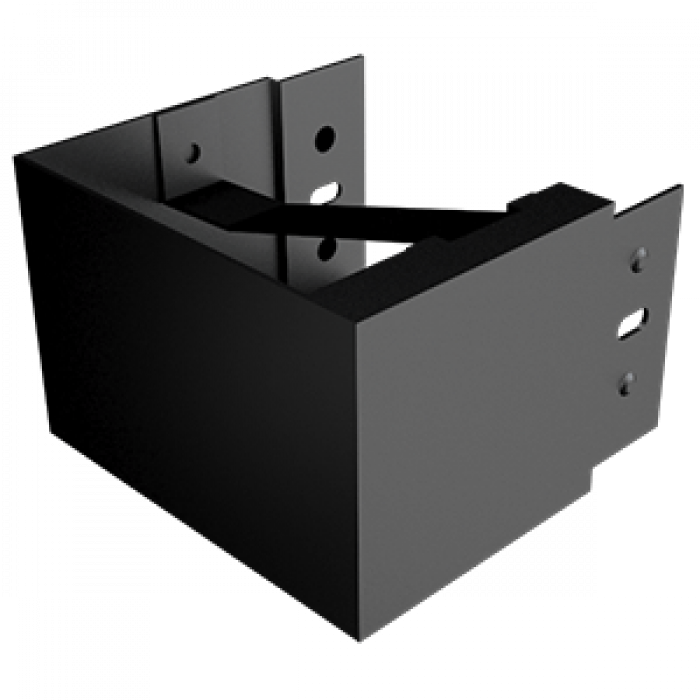

| 2 | 90° External Angle |

| 3 | 135° External Angle |

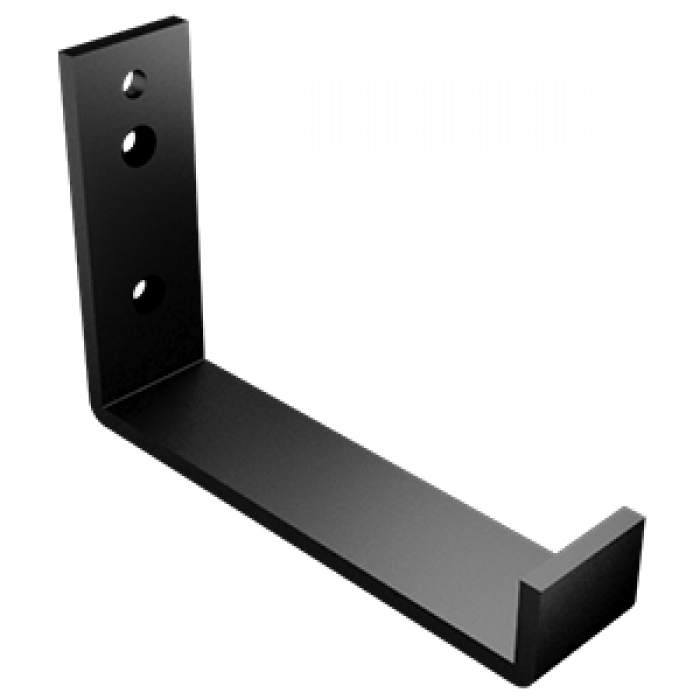

| 4 | Fascia Bracket |

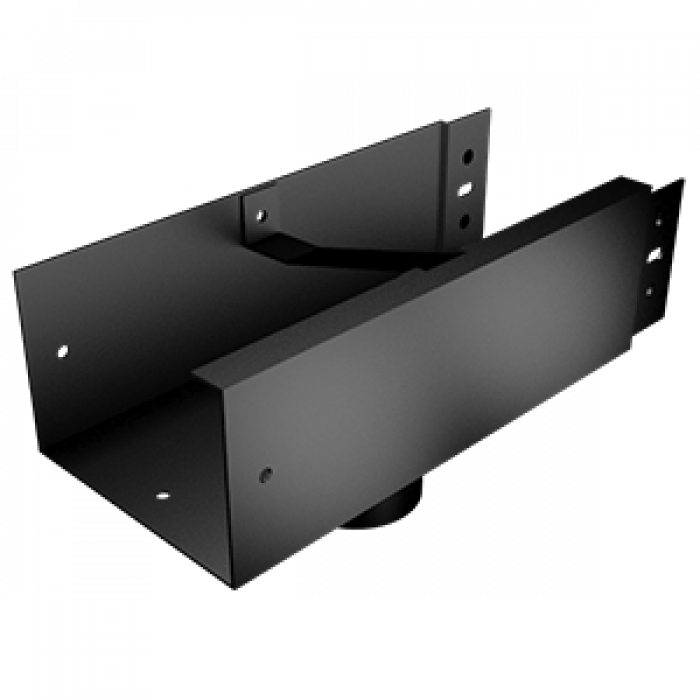

| 5 | Running Outlet |

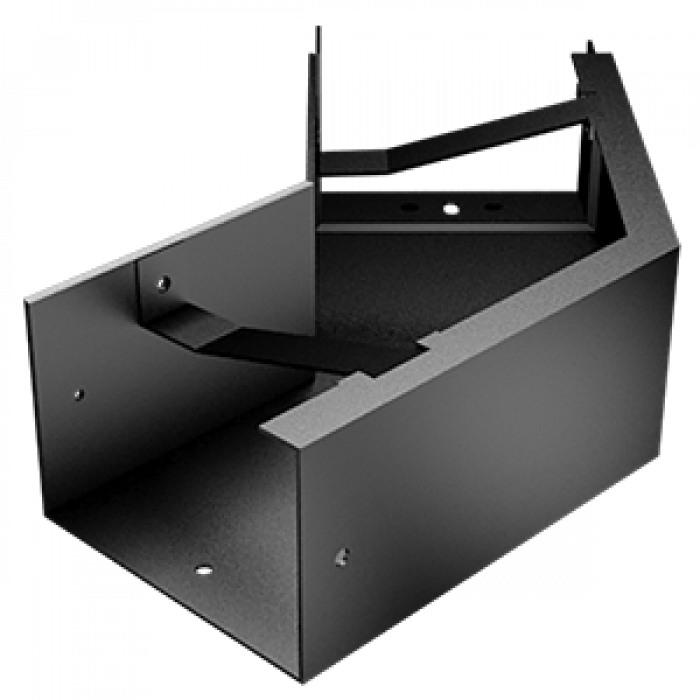

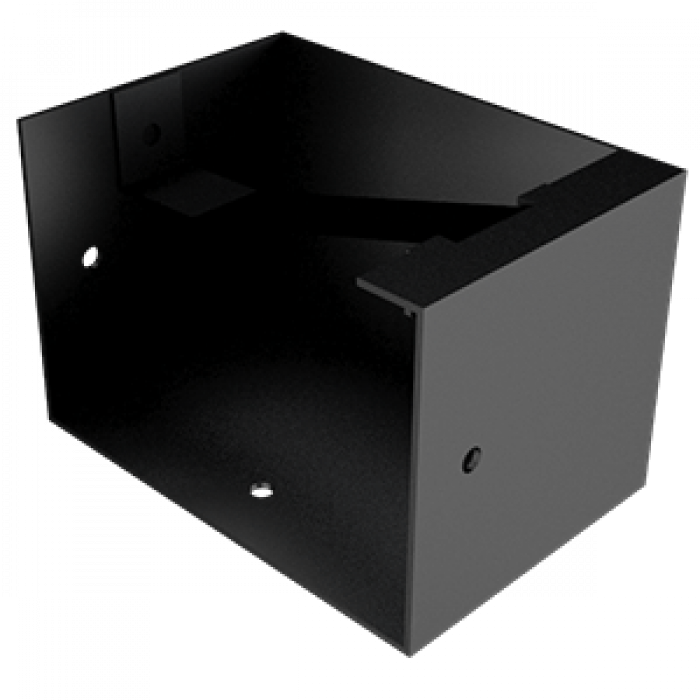

| 7 | 90° Internal Angle |

| 8 | 135° Internal Angle |

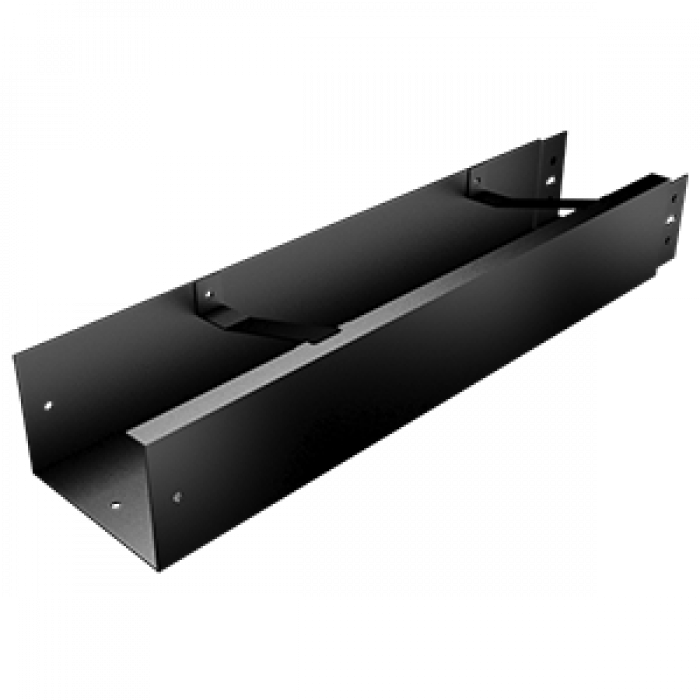

| 10 | Gutter Length |

| 12 | Union Connector |

| 13 | Right Hand Stopend |

Composition and Manufacture

- High Strength Aluminium Sheet 1050AH14

- Fittings made by cut/ mitre and welding

- 100% recyclable

- Radius and Special fittings can be provided

- Mill finish or powder coated to specific RAL/BS colour

- Lightweight

Installation of aluminium joggle joint box gutters

The pressed aluminium joggle joint box gutter is to be fitted on Legion brackets at 750mm centres, with an additional bracket required for all running outlets and angles no further than 375mm from the joint.

For Direct Fix, the gutter is to be secured via pre-drilled holes at 750mm centres with M5x25mm stainless steel countersunk screws (dependent on substrate). All fittings should also be secured via the pre-drilled holes.

Joints are to be made by applying two beads of Arbosil 1096 Low Modulus Sealant onto the plain-ended gutter; the joggle joint is located from above and secured using M6x20mm aluminium bolts, neoprene washers and nuts.

Expansion gaps of 3-4mm to be left between butt ends.

Full fitting instructions are supplied with every delivery.