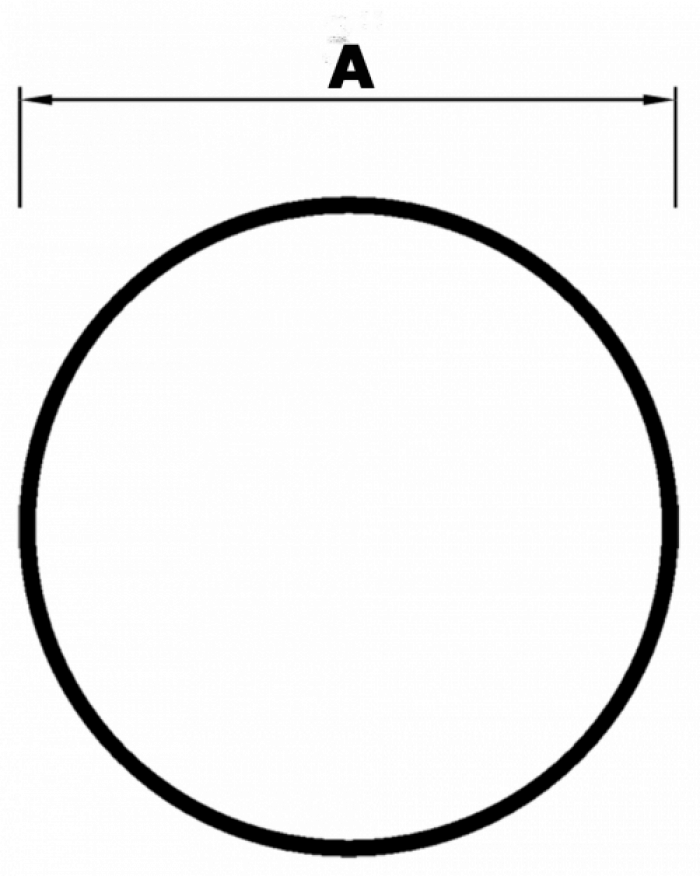

| A (mm) | A (inches) |

|---|---|

| 63 | 2½ |

| 76 | 3 |

| 101 | 4 |

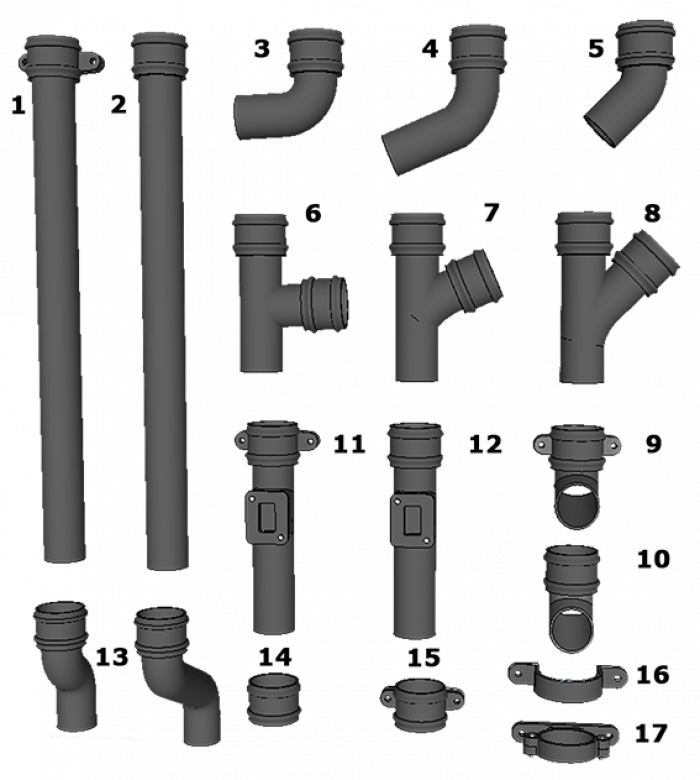

| Number | Item |

|---|---|

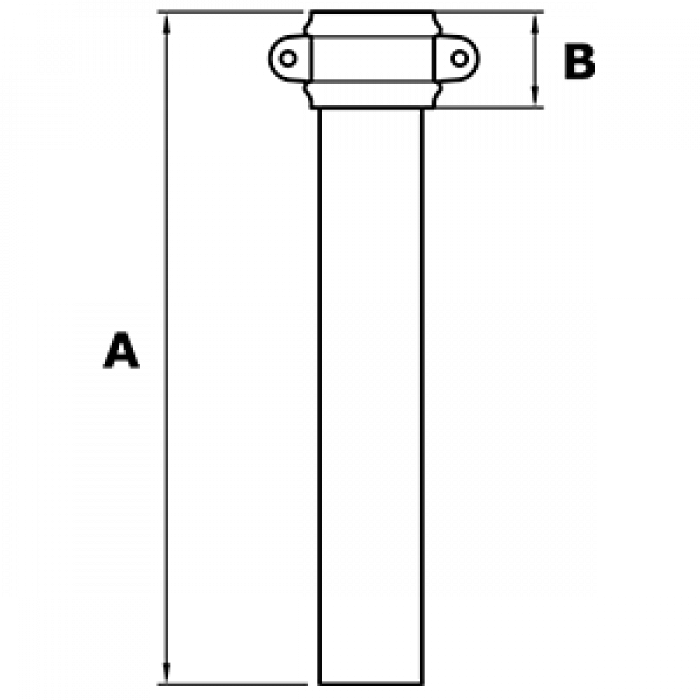

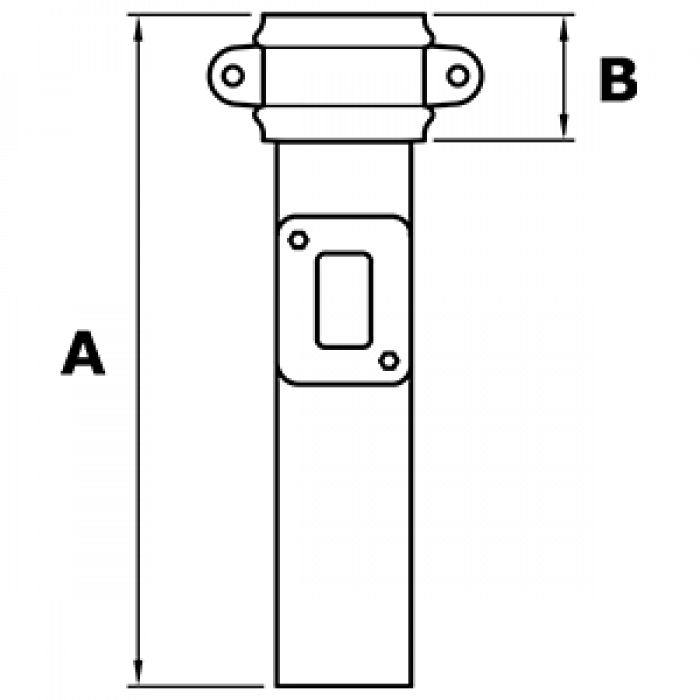

| 1 | Pipe Length with Ears |

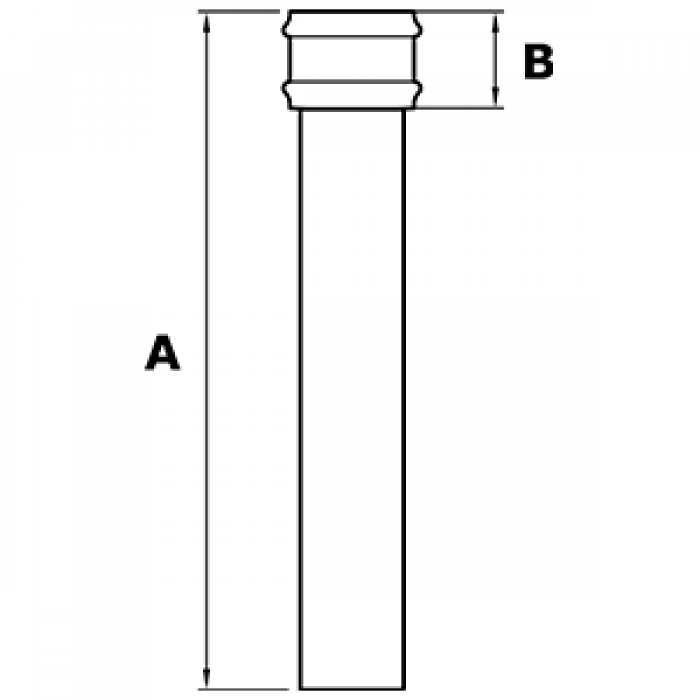

| 2 | Pipe Length without Ears |

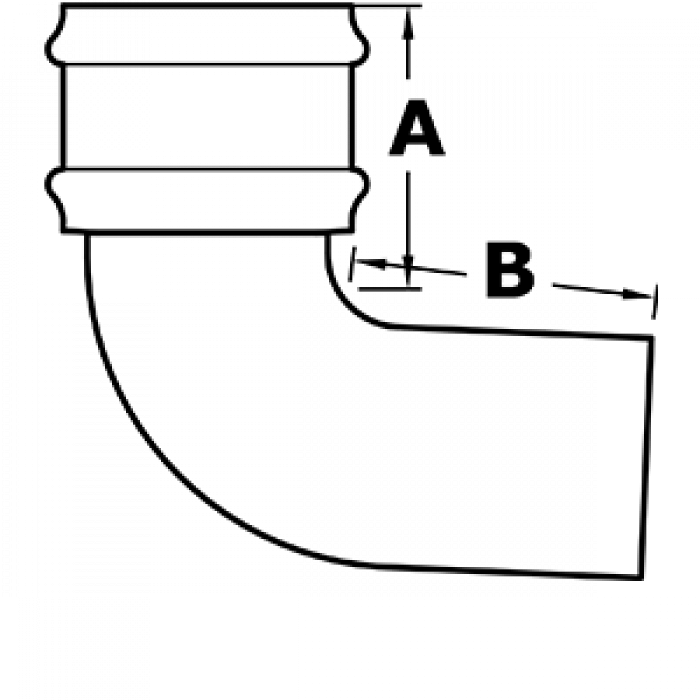

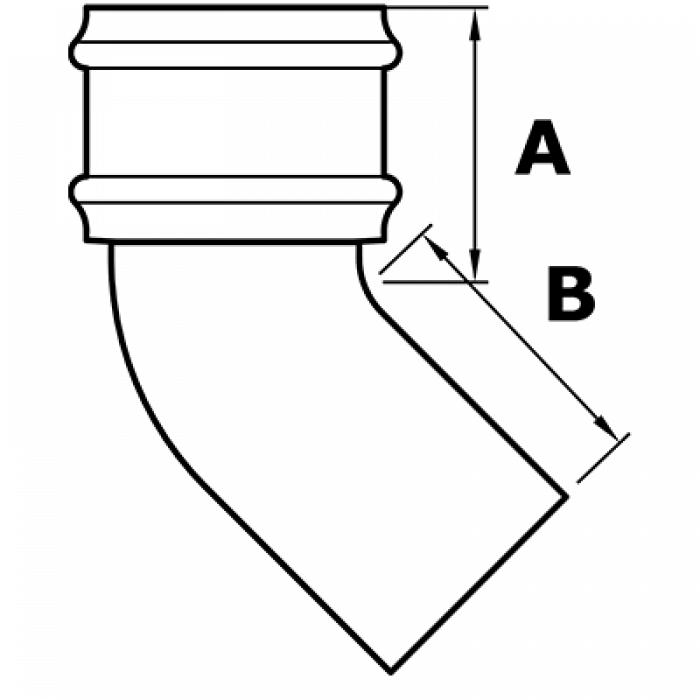

| 3 | 92.5° Bend |

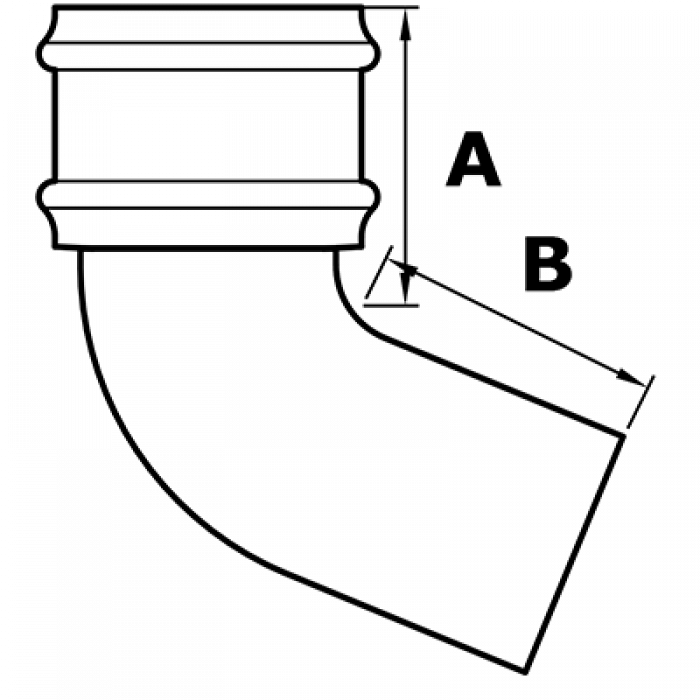

| 4 | 112° Bend |

| 5 | 135° Bend |

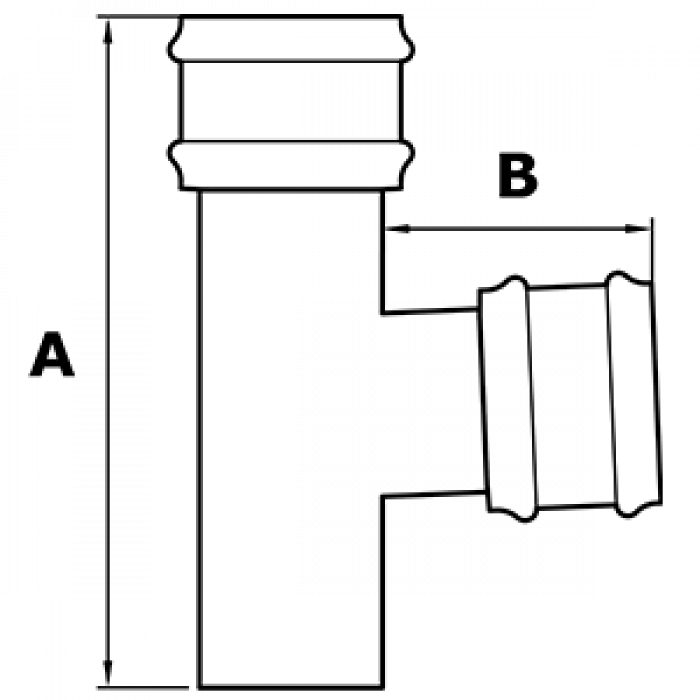

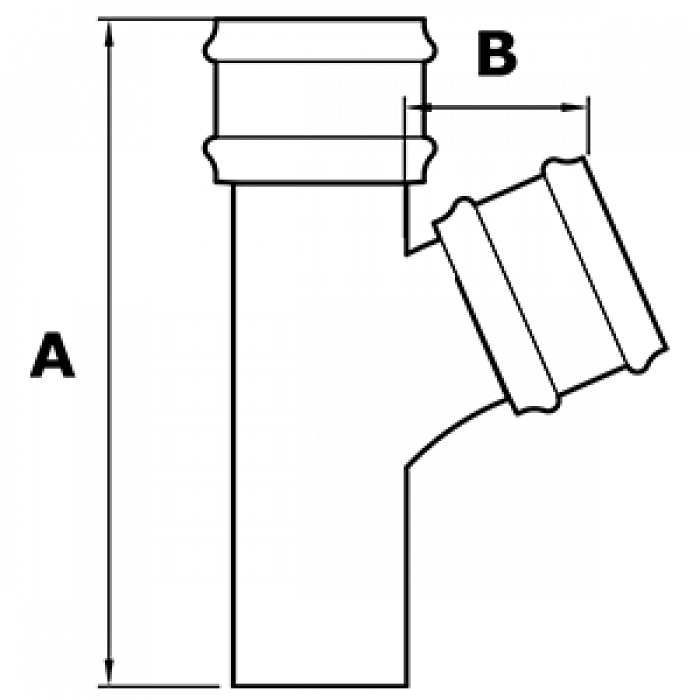

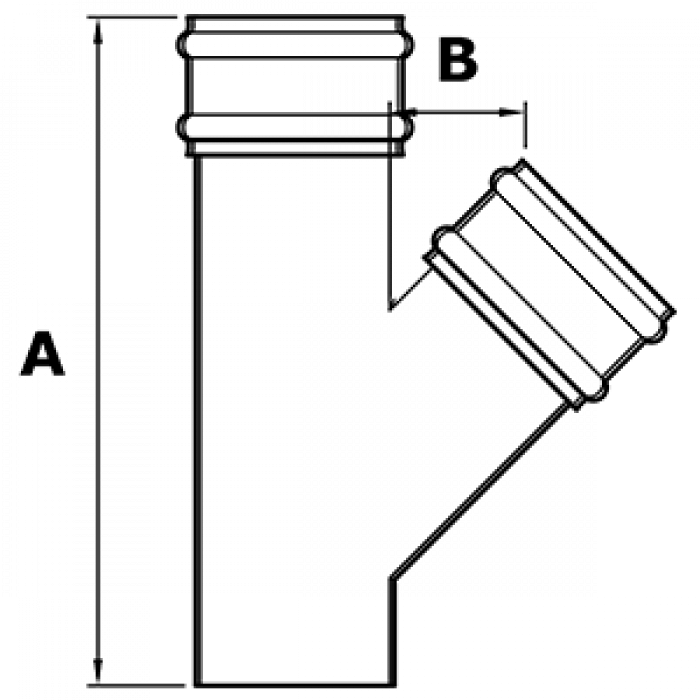

| 6 | 92.5° Branch |

| 7 | 112° Branch |

| 8 | 135° Branch |

| 9 | Shoe with Ears |

| 10 | Shoe without Ears |

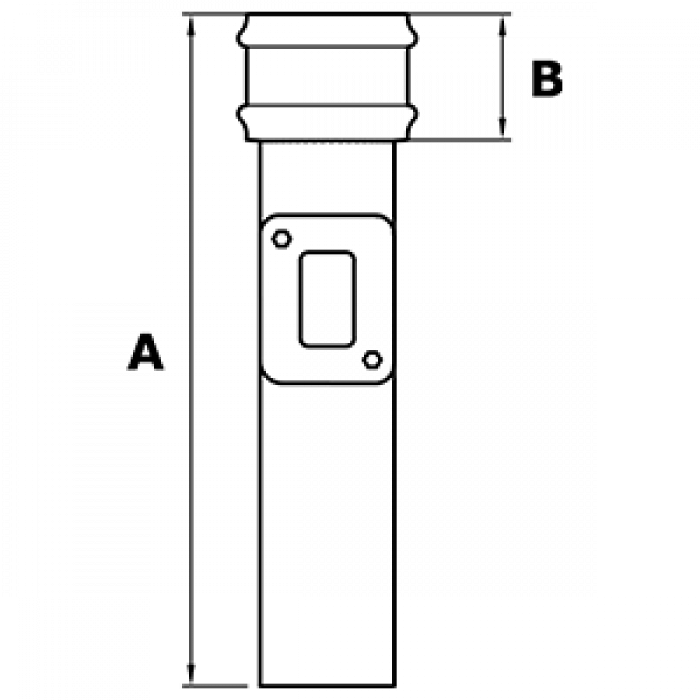

| 11 | Inspection Pipe with Ears |

| 12 | Inspection Pipe without Ears |

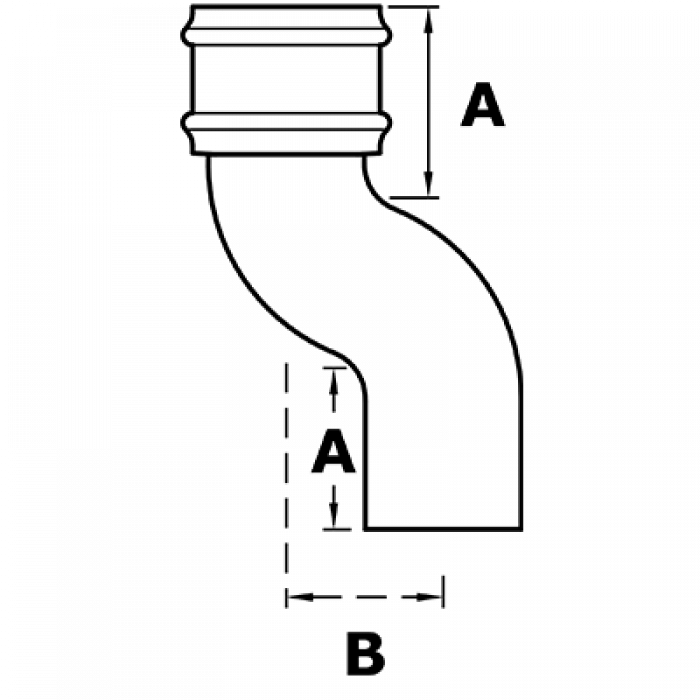

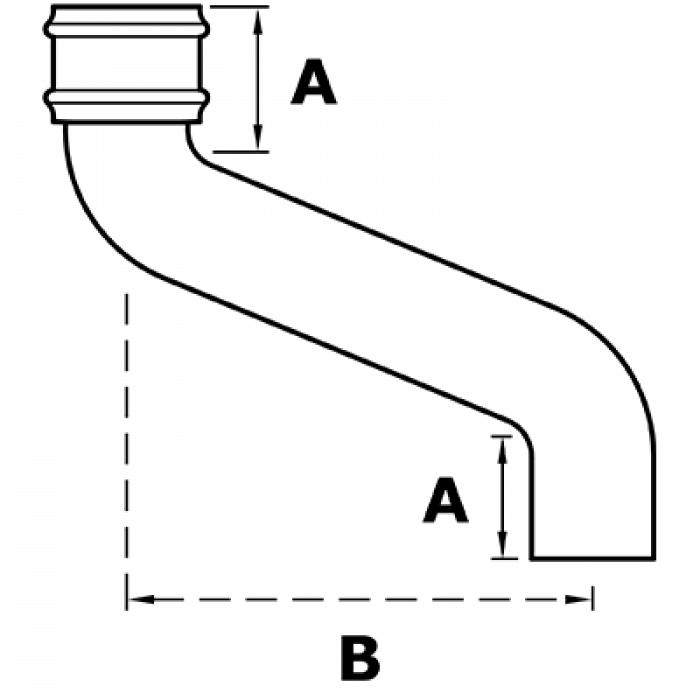

| 13 | 1 Part Offsets |

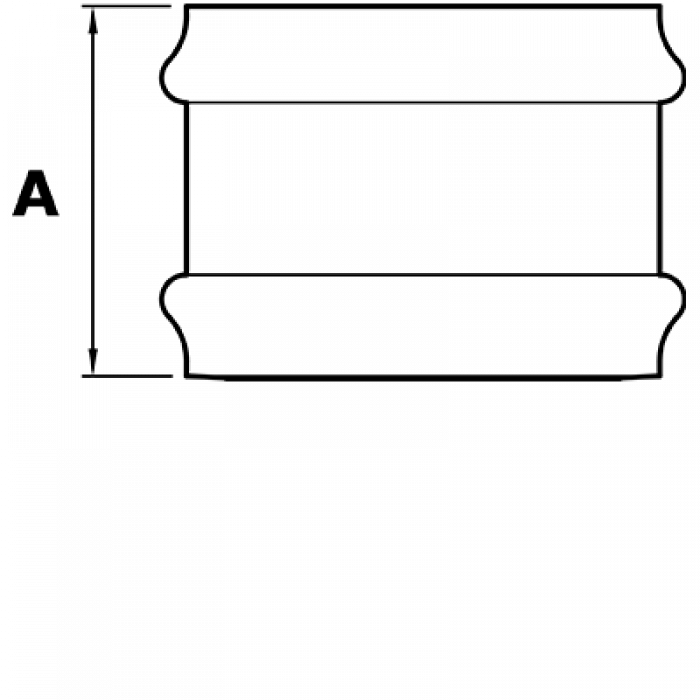

| 14 | Loose Collar without Ears |

| 15 | Loose Collar with Ears |

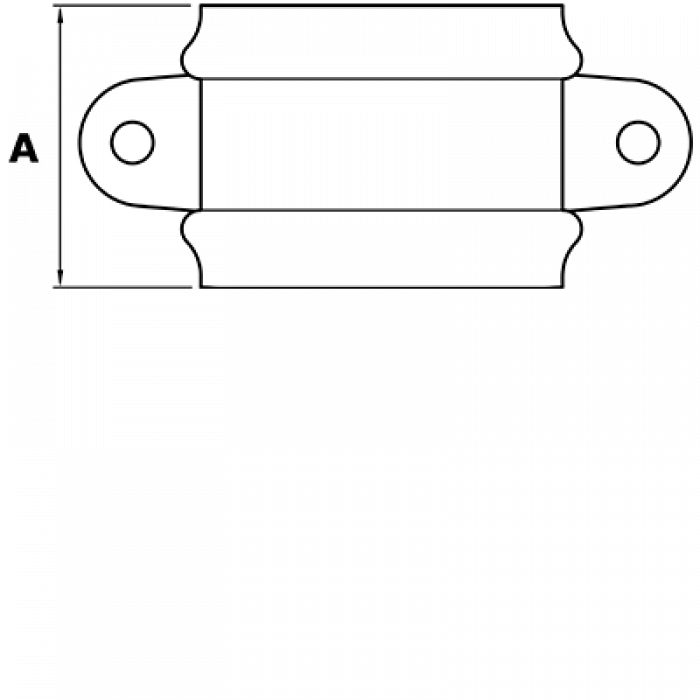

| 16 | Earbelt Standard |

| 17 | Holderbat Standard |

Composition and Manufacture

- Traditional Sand Cast Iron

- Manufactured to BS460:1964

- Bespoke fittings are available on request

- Complies with all Listed Building, Heritage and Conservation requirements

- Supplied Transit Primed or Factory applied wet paint finish in semi-gloss black or to a specific RAL/BS colour on request

- Life expectancy of over 100 years

Cast Iron Downpipe Installation

Eared pipe to be secured to substrate using 75mm or 100mm pipe nails or M8x75mm Hex head mild steel coach screws at maximum 2m centres in accordance with BS8230.

Non Eared pipe to be secured via standard earbelt or holderbat to substrate using 75mm or 100mm pipe nails or M8x75mm Hex head mild steel coach screws at maximum 2m centres in accordance with BS8230.

Access to be provided at the base of each downpipe for maintenance purposes, in accordance with BS EN 12056-3:2000. The “Britannia” shoe or access pipe are acceptable options.

Pipe Length with Ears

Pipe Length without Ears

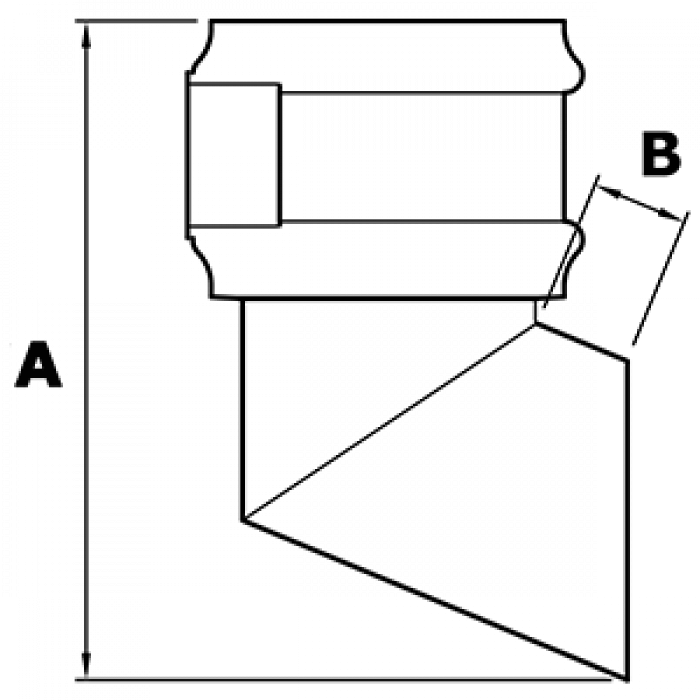

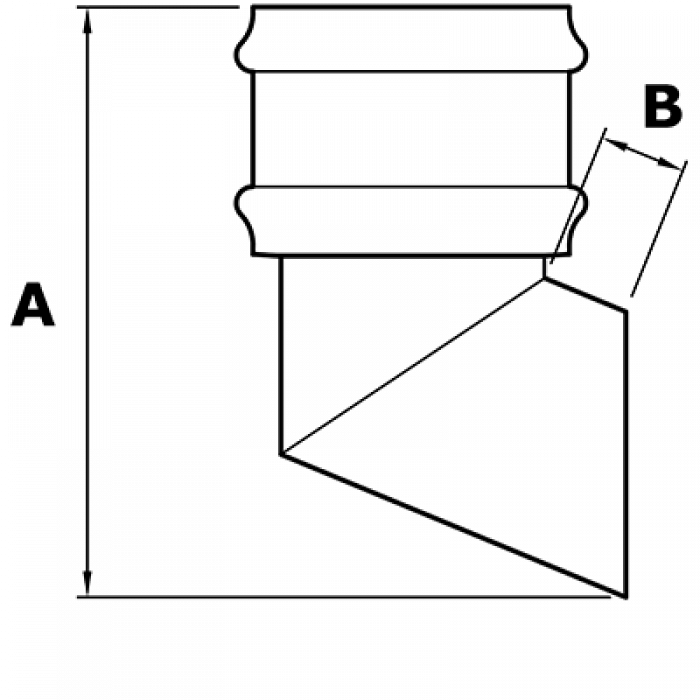

92.5° Bend

112° Bend

135° Bend

92.5° Branch

112° Branch

135° Branch

Shoe with Ears

Shoe without Ears

Access Pipe with Ears

Access Pipe without Ears

Small Offset

Large Offsets

Loose Collar with Ears

Loose Collar without Ears

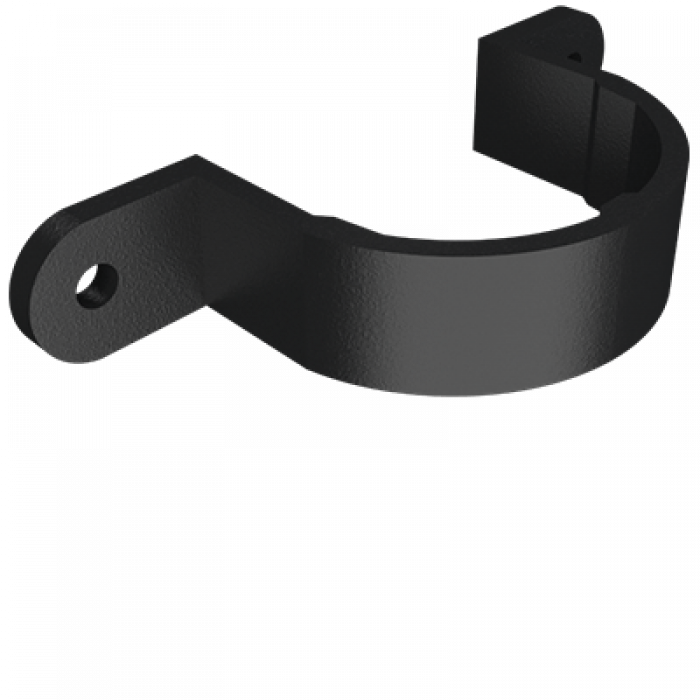

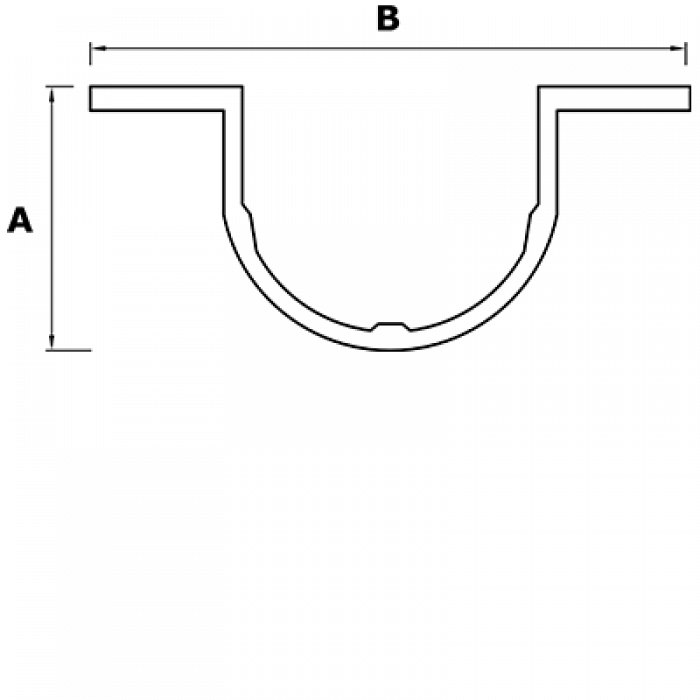

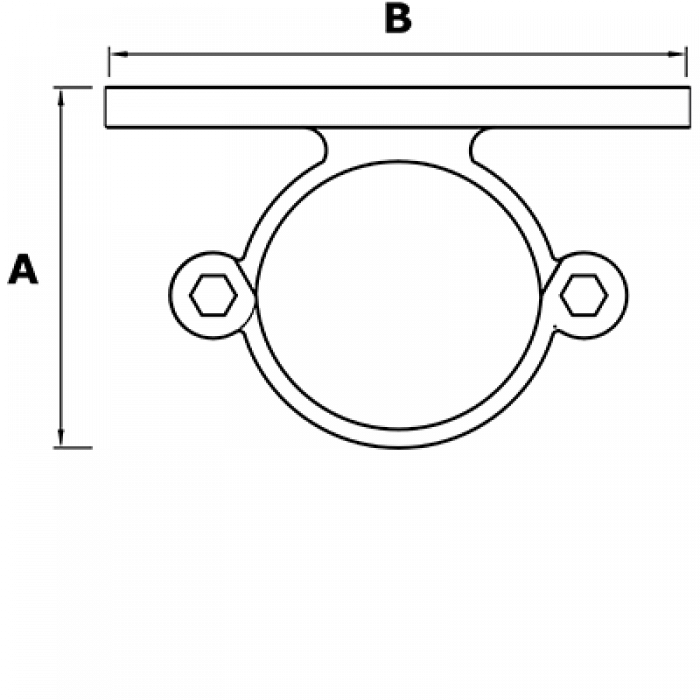

Earbelt Standard

Holderbat Standard